Hi there:

Before I get to our fresh translation, I'd like to send my best wishes to our subscribers in Hong Kong, which is still in the throes of its worst COVID surge. Among these readers are personal friends and family members who have been kept largely homebound for weeks now. Hang in there.

To the best of my knowledge I don't have any Ukrainian and Russian subscribers, but if any readers from these two countries stumble upon this issue, obviously my thoughts are with you too.

Our latest selection comes courtesy of Lai Lin, who provides a vivid, reflective and at times humorous account of his recent stint at a smartphone factory. The piece was first published in Chinese by The Story Plan on June 7.

Take care and see you soon.

—ML

Beating Pain, Boredom and Discipline: Recollections of a Smartphone Factory Worker

By Lai Lin

Edited by Pu Moshi

1.

Four a.m. The factory floor was bathed in the warm glow of white light.

Before each of the six assembly lines was mounted a 36-inch monitor that displayed constantly updated figures reflecting worker output. The data encompassed production, testing, packaging and boxing.

The persistent hum of factory machinery had the sleep-inducing effect of a lullabye. My neighbor Qin Xiaojun gave me a gentle kick and yelled with a distorted expression: "You deaf or what?"

I was indeed near deaf. It was my seventh month at the factory.

My stint started in October 2020 after the weeklong National Day holiday.

With all the major smartphone brands on the verge of launching new models, factory owners ramped up hiring. Middlemen got in on the action by teaming up with shell companies and posting misleading job ads.

If you browsed online job postings at the time, positions that didn't require education credentials all boiled down to regular worker openings at the end of the day when you pierced through the fancy titles. No amount of caution could avoid this outcome. The subterfuge was so heavy that it was common for factory newcomers to realize in their initial chitchat that none of them applied for the same position.

Seasoned workers are smarter, negotiating pay levels with headhunters directly. A single factory typically works with several agents. The middleman business was fiercely competitive. Veteran jobseekers sniffed out pay trends of any given year quickly. The most cunning of them shopped around, forcing headhunters into bidding wars that would leave the lesser funded agents underfunded.

I had originally applied for an hourly position, only to discover part-time positions did not include meals, which posed a financial hardship. Meanwhile, full-time posts came with a daily meal subsidy of 20 yuan (US$3.2) and a newcomer bonus of 3,000 yuan after 15 days of service.

To put food on the table, I ended up applying for a full-time job, Fifteen days into my stint, 200 yuan was wired to my account. "We never said the bonus would be issued in a single lump sum," my agent told me in a righteous tone.

The most important step before joining a factory as a regular worker is the physical exam.

The physical for regular workers is the most stringent out of all industries. It's a common sight for some 100 people to swarm at each window counter at the hospital, while no seat or floor space is left unoccupied. Urine test, EKG, eye exam, breathing frequency, height and weight measurements—no stone is left unturned. To facilitate the process for prospective hires, headhunters typically pay for the physical up front—before deducting double the cost from your paycheck down the road. So the popular online joke went that if you're not feeling well and can't afford a medical checkup, just apply for a job at an electronics factory. Not to be tongue-in-cheek, but this is actually a common occurence.

After the physical came three days of training. My company was quite kind, paying us 80 percent of our daily salary each day. Their main concern was that we wouldn't pay attention during the training sessions. Our instructor was thorough, covering everything from the national quality control scheme China Compulsory Certification, also known as 3C, to 6S, the detail-oriented work ethic that originated in Japan. He made a point of using technical jargon in every sentence, even showing off an English phase or two from time to time. We understood the English words in these phrases, but put together they simply made no sense. An older colleague who sat next to me was unimpressed. "What am I doing at an electronics factory if I could bloody understand language like this?" he fumed.

But everyone was on the same page when the instructor warned that all electronic devices were banned from the factory floor. Half of the recruits bailed instantly.

2.

The production line I joined was in charge of smartphone assembly.

Our factory had just issued marching orders, assigning some 30 fresh hires to our team. The leader of the production line was newly promoted. A day ago, he was an all-purpose worker at another factory. Except for the production equipment, everything was brand new.

We had meeting after meeting. The factory was heavy on bureaucracy. During my first three days on the job, the leader of my production line held at least 10 internal audits on nitpicky issues. The leader was from Qinghai Province. He loved to end every single meeting with the line: “I got here from the boondocks, step-by-step, on account of my own hard work.”

My first position was camera installation. The brand involved was a major one, with this specific model a low-end product geared toward foreign markets. Even though it was a cheap model, the phone was generously equipped with three camera lenses. Installing a camera lens entails applying finger pressure on the lens, so that it slides into a designated slot. My assignment was 2,000 phones a day, which meant I had to press 6,000 lenses into place every day.

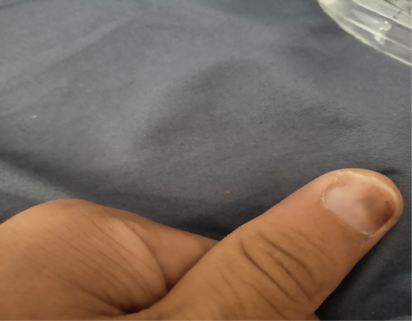

My hands were in constant motion during the daily 10~hour shifts. A few days into my stint, I started to feel pain in my thumbs and index fingers. At first, the pain was minor, but as time went by the piercing sensation became inreasingly severe. Every time I pressed a camera lens into place it felt as if a needle had poked through the nail of each thumb. At the end of the workday my fingers felt shattered.

My thumbs overwhelmed, I tried to improvise my finger movement in a countless number of ways, but those two digite were the only ones that could get the job done. If I fell behind in speed, the next step in the assembly line would be kept waiting, which would lead to a backlog. All I could do was suck it up and give myself pep talks while counting the number of phones I had installed cameras on. I would tell myself: "Today I equipped 2,000 phones with beautiful eyes."

But soon I was on the verge of collapse from the unbearable pain.

A week later, clots appeared under the nails of my thumbs due to ruptured capillaries. The pain increased, and counting the number of phones I had worked on offered no more consolation. I altered between states of emotional breakdown and mania. It felt as if I was forcing myself to endure torture that was thrust upon me. I briefed the leader of my assembly line during our lunch break. He accused me of not being able to handle hardship. He followed up by saying my technique was flawed and offered tips.

In the afternoon, I followed his instructions step-by-step, but the pain was still unbearable.

I approached the assembly line leader again, to ask for a transfer. He blew me off, again attributing my request to an inability to cope with hardship. Furious, I slammed the door on him after a brief argument. I thought my supervisor would compromise, envisioning him lecturing me on my incompetence the next day in a condescending manner while letting it slip a transfer was imminent.

After all, in a world where humanitarianism is the rage, both parties taking a step back was the best solution. I had rehearsed our conversation in my head repeatedly, refining my own lines so I sounded sufficiently diplomatic.

The next day, when I arrived on the factory floor with high spirits, I spotted two workers sitting at my workspace, already engaged in my usual tasks.

"What are you doing here?" my supervisor asked in an incredulous tone.

Eventually my supervisor arranged for a transfer after my headhunter intervened, but the incident sowed a division between the supervisor and I.

It also dawned on me that the single defining feature of an electronics factory was that it never lacked manpower. In that sense, factory managers never practiced humanitarianism.

3.

After I switched positions, my neighbor became Qin Xiaojin, a 21-year-old with a passion for gaming. He had bought at least 300 games on a prominent online gaming platform. Immersed in the virtual world of swordplay and combat, he was quiet at work. We had similar interests and personalities, which led us to quickly open our hearts as if we were long-lost soulmates.

Our tasks, which were not part of a critical project, demanded a quick turnaround. As we became jaded, we tossed all knowledge of 3C and 6S to the wind and started goofing around. As phones began piling up, we did a sloppy job of quality control. When we came across malfunctioning screens, we passed them to all-purpose colleagues, who simply banged the handsets on the floor a few times until the screens flashed. "What we're doing is churning out trash for our foreign friends," a colleague quipped.

Our factory was a sealed building without windows. The only source of information was chatting with colleagues. Qin Xiaojun and I started out with gaming before moving onto current affairs, then the economy, then our assembly line leader's bald head. We spoke our minds and enjoyed our conversation immensely. After work we read up on various topics so we could start new subjects of conversation the next day.

But as time passed, the two of us ran out of topics.

We were fully cognizant of this unspoken fact, to the point where when one us raised a topic we had covered before, we'd pretend we were confused and feign intense interest, even if we knew the answer by heart. That's why I heard a breakdown of the skillset of Yasuo, the League of Legends character, three times in a single week, and why to this day I can recite Arthur Morgan's character background. (Morgan features in the video game Red Dead Redemption 2.)

If we were interrupted by our supervisor, we'd use the same curse word and break out in laughter. If someone played a cheesy ballad, we would swear again and also erupt in laughter. As well as we could pretend that we were cracking the joke for the first time, sometimes we could detect a trace of disappointment in each other's gazes. The fact is we had long exhausted our conversation material the day before, while the number of phones passing through the assembly line was endless.

Talking to each other was the only thing that made use feel alive.

Night shifts were the worst. If there was no chatting on the factory floor, it felt like a ghost town. Anyone who's worked at an electronics factory knows that night shifts are easier than day shifts. Supervision is lax. There are no big bosses dropping in and the assembly line leader is less strict. As long as you finish your work on time, reasonable recreation is allowed.

Sometimes my colleagues would smuggle in USB boom boxes.

Come the wee hours, techno, TikTok hits and classic oldies would start playing from different corners. Thus emerged a circular hierarchy of songs. Those who played techno looked down on TikTok hits, while those who played TikTok hits considered oldies outdated. Meanwhile, the oldies listeners deemed techno outside the mainstream. But at the bottom of the hierarchy was colleagues too poor to afford their own stereo system.

USB sticks were easy to smuggle in but hard to smuggle out. Company policy banned workers from leaving the factory floor with any type of electronic devices. Yet to refresh your playlist you had to take your USB stick back to your dorm room. Once a colleague on my production line who was an active music listener was so brazen as to hide his USB stick in the crotch area of his pants. That sent the metal detector beeping and he was busted instantly.

Caught red-handed, there wasn't much chance of a defense.

Ultimately the colleague was fined half a month's salary for causing a nuisance. The subseuqent absence of stereos irked those who freerode on the music, thus landing the colleague at the very bottom of our hierarchy.

4.

The amount of turnover at an electonics factory resembles the traffic at a Chinese train station.

When I first arrived at the factory, I had five roommates in my dorm room. I made a point of cultivating ties with my roommates, remembering each of their names and interests, even going to the extent of treating them to a meal. Two weeks later, I still had five roommates—five new ones. From then on turnover was quick. My five roommates were often replaced before I could remember their names.

As I became a veteran, it was common to see new arrivals quit and leave the same day. Eventually I began ignoring everyone, considering they were all on their way out anyway. As a result, I didn't have much of a social life, either at work or during down time.

Apart from not being able to make any friends, I also had to be on guard. There were so many people at the factory. Out of all personal items, dust caps were a hot commodity.

Just before work one day, I left my dust cap on a partition board when I went to the men's room. When I returned, the dust cap was gone. I couldn't work without a dust cap, so my supervisor found me an old one. During lunch break that day, I left the dust cap in my locker and forgot to lock it. Indeed, the cap went missing again.

In the heat of the moment, I had no choice but to become a copycat. Many of the lockers in our changing rooms were unlocked. I canvassed a bunch of changing rooms before finally landing a dust cap. After work that day, I cautiously tucked my dust cap deep inside my clean room suit and made sure my lock was sturdy enough. Yet the next day I was blown away by the scene before my eyes. My locker had been ripped open. A quick inventory revealed no missing items—except for my dust cap.

After losing two dust caps in three days, a colleague joked I was up against the League of Legends character Sylas, who is known for copying the moves of his opponents. From then on, I always kept my dust cap in the left pocket of my pants.

By my second month on the job, I learned how to fine tune my mindset.

I broke down my workday into blocks. Seven a.m. to 11 a.m. was calm period. It was only the start of the day. There was no point in getting worked up. Eleven to noon was anticipation period. Lunch was only an hour away, so I had to stay upbeat. One p.m. to 3 p.m. was entertainment period. I kept my frustrations at bay by chatting with my neighbors. Three to 5 was meditation period, when I let my imagination run wild. Five to 6 was perseverance period. I just had to hang in there for another hour and it'd be the end of the day.

It felt as if all the anticipation in my life was centered around the end of the workday.

The final of the 2020 League of Legends world championship took place on Oct. 31, pitting the South Korean team Damwon Gaming against China's Suning, which enjoyed home court advantage in Shanghai. The match coincided with night shift, which ran from 7 p.m. to 11 p.m. Match point arrived during dinner break. (Damwon Gaming won 3-1.) Some 40 percent of workers ended up showing up for night shift late. One assembly line comprising predominantly men was so shortstaffed it couldn't start the shift. Just as supervisors were about to report the absences, the latecomers strolled in en masse wearing expressions of disgust. One of them bellowed as he walked: "Utter trash! Four dogs could've won that game." The second half of the shift was initially accentuated by rancor and hot tempers. Everyone wanted to air their grievances.

We reviewed the match in detail, identifying Suning's weaknesses and its mistakes. Three of us reconstructed the entire game, move-by-move: planting a spy, signaling with smoke, destroying an enemy unit and taking over their watchtower, obliterating enemy columns, first blood, the first mini-dragon and the first tactical mistake.

Workers on other assembly lines who disagreed with our analysis talked back loudly.

"The biggest mistake came in the 21st minute!" one colleague argued.

At one point the conversation drifted to gossip about the gamers who took part in the final, which drew a few female colleagues into the fold. Someone began telling a history of recent top gamers, sparking a heated discussion over who was the all-time great.

Productivity was stellar that night.

As our conversation winded down, we surmised: "There's no hope for Chinese gamers!"

5.

Apart from pointless chitchat and dirty jokes, our other form of entertainment was smoking, which required an meticulous and elaborate system. Open flames or fires are banned on the factory floor, with both matches and lighters among the contraband. Smoking was also banned. Our company took the smoking ban extremely seriously, issuing repeated warnings and even going so far as stationing a safety inspector near the toilets.

Our response was to stash lighters and cigarettes inside trash bins or in the water closet behind the toilet bowl and taping them to the bottom of urinals. The problem was every assembly line was allotted only a single toilet pass. Smoking alone without a lookout was too risky and not worth taking the chance. Thus the united and brilliant working people at our factory networked across assembly lines and organized group smoking sessions.

Timing was critical, so we came up with the idea of designating a smoking coordinator on every assembly line. At its peak, there were as many as a dozen smoking sessions scheduled each day, especially in the second half of night shifts. Members of the smoking teams kept tight watch on the time, setting off with toilet passes as soon as the scheduled session arrived. Co-ordination was superb, with team members arriving within two minutes of each other.

Each session usually involved three people. One was planted drinking by the water cooler. If an inspector was en route, that person would crash his glass against the cooler, which would alert the second lookout, who'd be washing his hands inside the toilet. He would alert the smoker inside the toilet partition by increasing the faucet flow and splashing water on his face. The smoker would immediately put out the cigarette, dump the butt in the trash can and pop a stick of gum into his mouth. If all went according to plan, the three members would rotate until each had the chance to smoke.

To maximize these sessions, everyone smoked furiously. It would take less than five minutes for each trio to finish smoking. Once a colleague joked in the tone of famed comedian Yu Qian: "Smoking at this pace will cause lung cancer in three days." Refreshed from the nicotine high, we responded with boisterous laughter.

Qin Xiaojun's appetite for nicotine was voracious during that period.

He had to make three or four toilet runs a day. The colleague who covered for him said he was the ultimate addict. He later told me in private that he wasn't an addict and that in fact, he was barely a smoker. Smoking was just an excuse to slack off, he said, because he found the factory floor so suffocating.

Qian Xiaojun and I also went singing.

The two of us could only afford budget karaoke bars with faulty equipment. Once the two of us tried a karaoke bar based in a neighboring village. The catalogue consisted of mostly classic oldies. The only Jay Chou songs we could find were covers. We had no choice but to play songs on our phones and put them next to a microphone. Their mikes—which were not cordless—were so old that they had loose connections. We had to press their plugs against the stereo system to make sure they worked.

We'd be engrossed in a song when the music would stop amplifying and a howl-like echo would reverberate through the makeshift building.

We were fed up. Qin Xiaojun decided to teach the owner of the karaoke bar a lesson by pissing on our dilapidated couch, only to have the move backfire on him. When we got back to our dorm, he noticed a wet patch on this pants. He touched the spot and sniffed his hand before giving a bedpost a ferocious kick.

Befuddled, our colleagues wondered what he had been up to that pissed him off so much.

"We went singing in a public toilet!" Qin Xiaojun growled.

Apart from singing, many workers also killled time in Internet cafes.

The residential area near our factory was covered with underground Internet cafes. Some of them didn't even have server rooms or unified operating systems. But even cafes that had a paltry few popular online games could land customers with a few shoddy videos playing on a screen.

Competition was intense, so cafes tried to outdo each other by offering special services. Come the end of the shifts and a few minibuses would appear outside the factory. Toting signs that said "free laundry and showers," cigarette-puffing cafe owners lingered nearby scouring for workers carrying clean room suits.

The underground Internet cafes charged 15 yuan for both a day pass and an overnight stay, so some of the bolder workers brought their bedding and a change of clothes to their cafes of choice. Their daily commute between Internet cafe and factory appeared to have no end.

There were days when I also couldn't see the light at the end of the tunnel.

Only on our scheduled days off would restaurants near the factory see a surge in business. But our conversations over dining out would inevitably end up on the topic of our assembly line leaders. To my dismay, it dawned on me during meditation period one day that our discussions never veered far from happenings at the factory. We were trapped in our factory spiritually even when were physically removed from it.

In the wee hours that same day, Qin Xiaojun yelled my name several times.

As the music playing on the factory floor increased in volume, I finally noticed Qin Xiaojun's face gesturing at me. He was keen on my thoughts on a certain video game. Fresh smartphones were being shuffled onto a conveyor belt under bright lights. I blinked, turned my attention to the pile of phones in front of me and yelled to Qin Xiaojun: "Fuck! I fell asleep!"